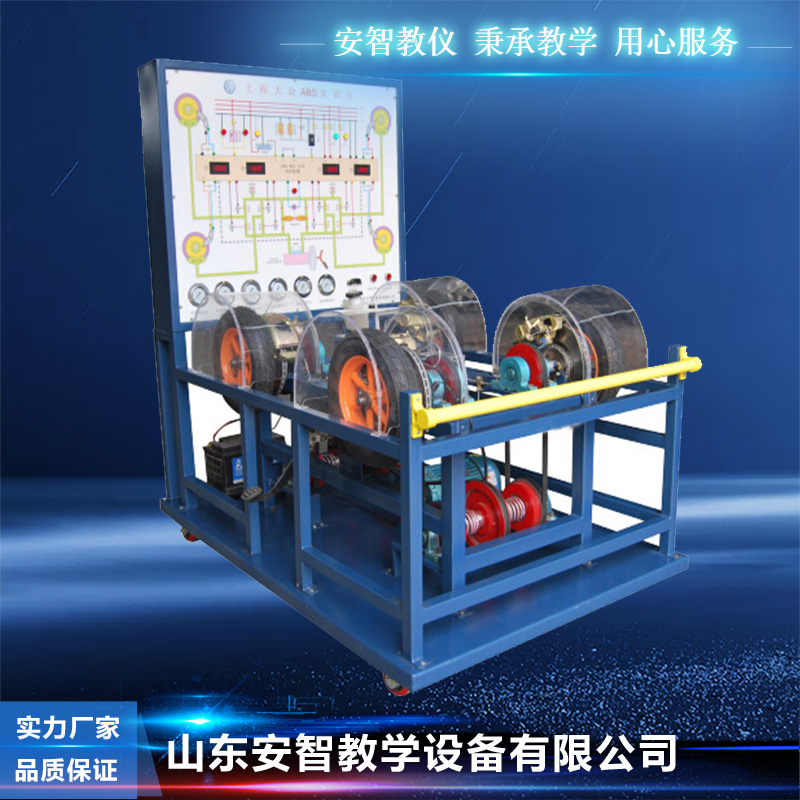

Model: AZ-1211

1. General Overview

Training platform to use automotive ABS/ASR; Brake system based with ABS/ASR; Schematic diagram of system operation, truly showing ABS/ASR during emergency braking; The system work process is applicable to various types of colleges and training institutions for automotive ABS/ASR Practical teaching needs of system theory and maintenance training.

Equipment composition: The training platform includes the following main accessories: ① ABS/ASR; Control unit assembly * 1 ② Castor * 4 ③ Brake master cylinder * 1; Set; ④ Brake wheel cylinder * 4; ⑤ Pressure gauge * 4; ⑥ Brake oil tank * 1 ⑦ Brake pedal * 1; ⑧ Converter assembly * 1; Set; ⑨ Three-phase asynchronous motor * 1; ⑩ Outer ball cage * 4 Set 4 brake discs.

3. Function description; 1) The training platform is equipped with a real automobile ABS/ASR Complete demonstration of ABS/ASR based on the actual brake system; Composition and structure of braking system;

2) Simulate vehicle driving. ABS/ASR When there are no system faults; ABS/ASR When it works, the brake pedal rebounds and is in an anti lock state; ABS/ASR When there is a system fault, ABS/ASR; Does not work, the brake pedal does not rebound, and is in a normal braking state; 3) There is the original ABS/ASR on the training platform panel; Standard schematic diagram and circuit diagram of the system (line color, line diameter, component symbols, connector symbols, etc.) and ABS/ASR Hydraulic working diagram, and can directly detect ABS/ASR on the circuit diagram; Circuit analysis and diagnosis of various components and faults; 4) Installed on board with 4 Pressure gauges that fully reflect the pressure changes of the brake master cylinder and the brake wheel cylinder, ABS/ASR; When the system is working, the pressure gauge pointers of each wheel constantly swing, indicating ABS/ASR; The system continuously applies pressure and unloads during operation; 5) The training desk panel is equipped with a diagnostic seat that can be connected to a dedicated or General Motors decoder. For ABS/ASR; The electronic control system performs ECU; Self diagnostic functions such as code query, reading fault codes, clearing fault codes, reading data streams, performing component testing, parameter setting, waveform analysis, etc; 6) Electronic control system detection function: The teaching panel is installed with a computer lead out terminal, which can be used to detect the resistance, voltage, frequency, and waveform of each sensor and actuator using a multimeter and oscilloscope; 7) The training platform is equipped with safety protection devices such as a main power switch and a protective net to facilitate cutting off the main power supply and carrying out safety protection.

4. Technical characteristics: 1) Bench size≥ Length 1.2m * width 1.1m * height 1.8m; 2) Frame material: National standard pipe material, seamless welding, reasonable and beautiful overall structure; The surface of the bench is processed through a series of processes such as welding, polishing, polishing, phosphating, electrostatic spraying, high-temperature baking, and the paint surface is solid and beautiful. 3) Main panel material: aluminum plastic plate weather resistance, wear resistance, high temperature resistance, high strength, corrosion resistance. 4) System circuit diagram spray painting method: UV; Printing (the system circuit diagram is completely based on the original maintenance manual circuit diagram drawn and spliced); 5) Test hole: high-quality nylon high-pressure safety type 4mm; Panel banana socket hole/PA66; High strength nylon/brass nickel plating/material plating compliant with RoHS environment protection 6) Bearing wheel: Made of nylon material, it is highly load-bearing and wear-resistant, with a wide wheel surface, providing ultra-high stability, flexible rotation, and outstanding durability. The dual bearing design provides more uniform bearing, pressure resistance, and impact resistance. 7) Three-phase asynchronous motor: voltage: AC380V 50Hz; Power: 3KW; Rotating speed: 1420 r/min;

5. Training Program: 1) Automobile ABS/ASR; System fault simulation and contact training; 2) Automotive ABS/ASR; Practical training on system structure composition and working process; 3) Automotive ABS/ASR; Practical training on disassembly, inspection, and replacement of system components;