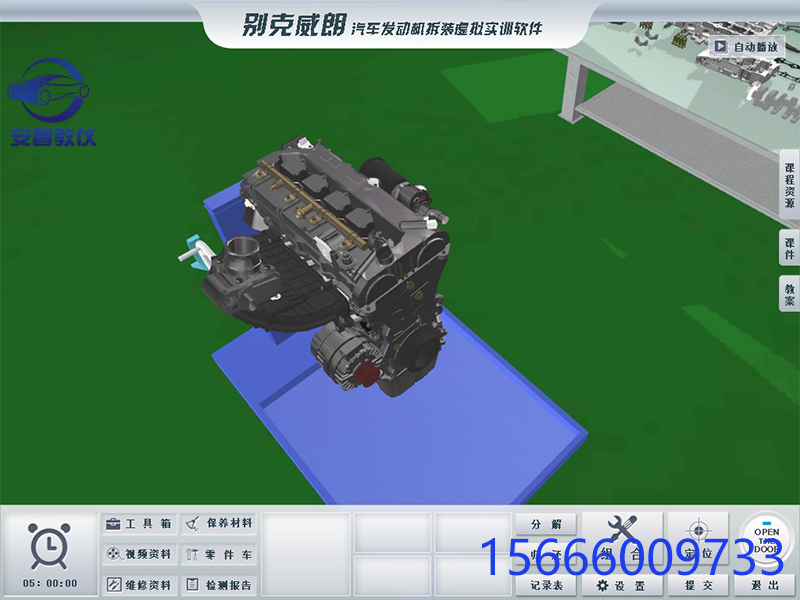

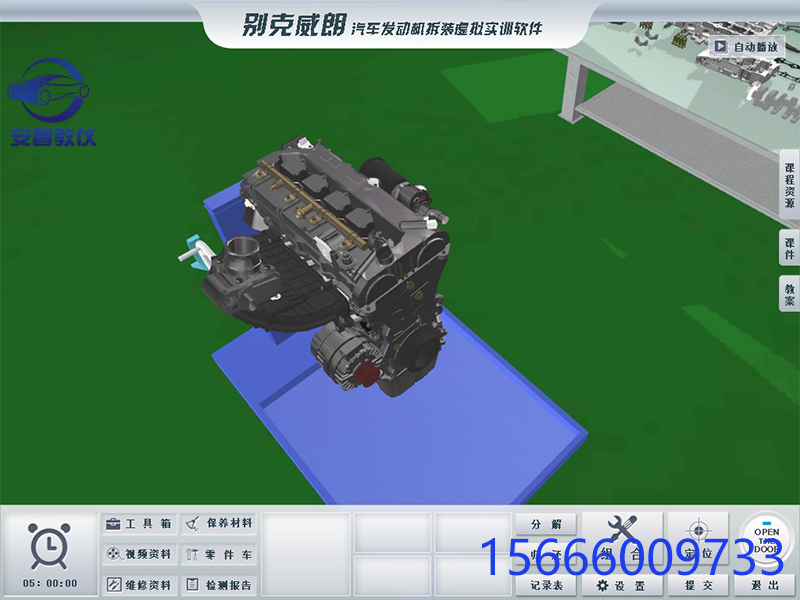

Product Introduction

Based on the disassembly and assembly process standards specified by the automobile manufacturer, combined with common precautions during engine disassembly and repair and the guidance of multiple automotive technology experts, it is customized with two modules and multiple sub modules for disassembly and installation, facilitating students to carry out special exercises; Provide teaching plans, courseware, assignments, and resource functions to enrich teachers' teaching and students' learning

Product Features

Develop R&D based on international competition level standards

The disassembly of each bolt is based on the competition level standard mode, fully in accordance with the international competition operation steps and actual combat mode. At the same time, a large amount of money has been invested to hire national automotive professional professors and senior automotive professional technicians to personally guide and cooperate in research and development

Based on the maintenance process design of Buick Weilang vehicles

The torque setting is fully in accordance with the maintenance manual standards,

Internal operation prompt judgment function

If a user makes an error during the exercise mode, the system will automatically send a voice alarm prompt to facilitate the user's learning

l & nbsp; Use various special tools for engine disassembly and assembly

The combination tools, special tools of Weilang series, common hardware tools and actual operating tools are exactly the same, more professional and more convenient!

Product Advantages

Standard process, highly professional

Buick Verizon provides disassembly and assembly processes, combines practical maintenance precautions, and provides guidance from multiple automotive technology experts

Real scene, personalized design

Highly simulated 4S store environment and various equipment tools, with strong interactivity, good versatility and fault tolerance, beautiful interface, user-friendly design, which can provide simultaneous operation by multiple people, and fast resource interaction

Easy to use

Text prompts, precautions, and error prompts for corresponding operation steps for 3D simulation scenes. Teachers and students can operate easily and stimulate students' interest in learning

High efficiency of teaching and learning assistance

Teachers conduct teaching demonstrations, timely guidance, and uation. Through the management center, students can query their practical training, improve their hands-on skills, and record and feedback in real time

Product Technical Parameters

General description

1. Development tool: Unity3D

2. Database: SQL SERVER 2008R2

3. Operating system: win7, win8, win10

4. The development model is based on the Buick Weilang 1.5 engine electronic control engine

5. The main function of the software is to conduct simulated disassembly and assembly training for Weilang engines, for teachers to conduct practical training and demonstration teaching, and for students to conduct practical training and operation learning. It has the function of timely interactive uation between teachers and students to meet teaching needs< br />

6. The overall software design process must comply with the 5S specification and be clearly reflected in the product< br />

7. The division of modules within the software must comply with the technological standards of the National Skills Competition< br />

8. The software adopts a C/S architecture, allowing smooth 3D virtual interactive operations, and supporting 360° Rotation, translation, near far interaction, etc< br />

9. The software is divided into two parts: the front desk is for teachers and students to practice and assess, and the back desk is for administrators to manage information such as teachers, students, and classes

Front platform

Login Registration

1. Student accounts can be registered independently by students on the front desk, or added by administrators on the background

2. The teacher account is added by the administrator in the background

Student login

Main page

1、Display student details, including name, student number, class, practice times, and assessment times

2、 You can modify an individual's login password

3、 Can support the avatar upload function

4、 You can view individual practice and assessment records, as well as assignments posted by teachers

5、 Select any module for learning

Learning Record

1. Students can view each step of their practiceIncluding time, content, and results

2. Students can uate themselves on each exercise and view the teacher's comments on themselves

3. You can quickly find based on exercise items

Practical assessment

1. Students can view each step of their assessment, including the time, content, and results

2. Students can uate themselves on each assessment and view the teacher's comments on themselves

3. You can search based on the uation item and exam name

Operation center

1.You can view the assignments posted by the teacher, download them locally, and submit completed assignments

2、 Can quickly find jobs based on conditions

Teacher login

Main page

1、 Display individual names and managed classes

2、 Upload a personal avatar

3、 Modify an individual's login password

4、 Publish Appraisal

5、 Enter the management center

6、 Select any module for teaching demonstration

Management Center

Practical Training Management

1、 View students' exercise records, including name, student number, class, exercise time, exercise content, and view each operation step of the student

2、 You can query by class, student number, name, and exercise content

Assessment management

1、 View the student's assessment records, including name, student number, class, exercise time, and exercise content, and view each operation step of the student

2、You can query by class, student number, name, and assessment content

job management

1、 View class assignments and download assignments uploaded by students for review

2、 Query can be performed based on class, student number, name, content, and review status

Publish Assessment

1、 The teacher terminal can publish assessment information, including exam name, exam duration, start time, end time, classes to be tested, and assessment items

2、 After publishing the assessment, students can take the exam within the corresponding time

Software disassembly and assembly training workshop scenarios include assembly disassembly and assembly stands, tool cars, parts cars, and elevators, oil recovery vehicles, etc.

Training simulation

Simulate the real operating environment of the National Skills Competition, and operate in accordance with the standard disassembly and assembly processes in the maintenance manual, including component disassembly and installation and maintenance, tool selection and use, and process processing. The software provides standardized disassembly and assembly process operations, including bolt disassembly sequence, bolt installation torque, and component lubrication. Interact with the scene through the mouse, allowing you to rotate, pan, zoom in, and zoom out through 360 degrees within the scene. Simulate disassembly, assembly, maintenance, and assessment in accordance with maintenance technical specifications.

Module division

Divided into“ Disassembly” And“ Install” Two major modules, including: engine assembly disassembly, engine peripheral components disassembly, camshaft cover disassembly, oil pan disassembly, timing mechanism disassembly, cylinder head disassembly, and cylinder block disassembly; The installation module includes: engine assembly installation, engine peripheral components installation, camshaft cover installation, oil pan installation, timing mechanism installation, cylinder head installation, and cylinder block installation. After completing the module disassembly exercise, the user can choose whether to proceed to the next step or exit. The mechanical assembly of the Weilang engine is completely made using virtual simulation technology, and can be interactively operated with the scene through a mouse. It can be rotated, panned, zoomed in, and zoomed out by any 360 degrees within the scene.

Main scene

Scene parameter settings

1. Resolution setting: Available at: 800× 600、1024× 768、1280× 720、1920× 1080< br />

2. Scene switching: You can switch between teaching scenes, competition scenes, and outdoor scenes< br />

3. Color Settings: You can set the colors of the scene interface< br />

4. Screen Settings: You can choose whether the scene interface is displayed in full screen< br />

5. Angle of View Selection: You can switch between the first angle of view and the third angle of view< br />

6. Prompt volume: You can adjust the size of the prompt volume

Operation mode

There are two modes: automatic and manual. In automatic mode, the software will operate independently and can be switched back to manual mode after pausing

Teaching plan courseware

1. The teacher can view all the teaching plans of the current operation module in the main scene, and can directly open the software for reference

2. Administrators can replace or add lesson plans and courseware in the background< br />

3. Students can view all the courseware within the current operation module, and can open it directly through the software for reference

4. Each operation module can support multiple lesson plans and courseware, and the lesson plan and courseware directory support the page turning function.

Course resources

The student account can view various course resources included in the chapter. The resources support multiple types of images, documents, videos, and flash animations

hold-all

Combination tools, Weilang series special tools, common hardware tools, etc< br />

1. View the information of the tool. There are 4 layers in total. Double click to select and use the tool

The tools included in the first layer include: 4 # - 13 # small hexagon socket, 9 # - 19 # medium hexagon socket, 20 # large hexagon socket, 21 # large hexagon socket, 22 # large hexagon socket, 24 # large hexagon socket, 27 # large hexagon socket, 30 # large hexagon socket, 32 # large hexagon socket, small ratchet wrench, medium ratchet wrench, large ratchet wrench, torque wrench 0_ 25. Torque wrench 25_ 100, torque wrench 60_ 320, Long Extension Small, Short Extension Small, Short Extension Medium, Long Extension Medium, Short Extension Large, Long Extension Large, Adapter Large in Rotation, Universal Extension Small, Universal Extension Medium, Universal Extension Large, TX55 # Large Torx Sleeve, TX20 Torx Middle Sleeve, TX30 Torx Middle Sleeve, TX40 Torx Middle Sleeve, TX45 Torx Middle Sleeve, TX50 Torx Middle Sleeve, TX55 Torx Middle Sleeve, TX60 Torx Middle Sleeve, FD5_ 5 Slotted medium sleeve, FD6_ 5 straight head middle sleeve, PD1 cross sleeve, PD2 cross sleeve, HW3 hexagon head middle sleeve, HW4 hexagon head middle sleeve, HW5 hexagon head middle sleeve, HW6 hexagon head middle sleeve, 13 # - 20 # medium length sleeve, 8 # - 13 # small length sleeve, E8 plum blossom middle sleeve, E10 plum blossom middle sleeve, E12 plum blossom middle sleeve, E14 plum blossom middle sleeve, E16 plum blossom middle sleeve, E18 plum blossom middle sleeve, and E20 plum blossom middle sleeve< br />

& nbsp;& nbsp;& nbsp;& nbsp;& nbsp; The tools included in the second layer include: 8 # open end wrench, 9 # open end wrench, 10 # open end wrench, 11 # open end wrench, 12 # open end wrench, 13 # open end wrench, 14 # open end wrench, 15 # open end wrench, 16 # open end wrench, 17 # open end wrench, 18 # open end wrench, 19 # open end wrench, 20 # open end wrench, 21 # open end wrench, 22 # open end wrench, 23 # open end wrench, 24 # open end wrench

The tools included in the third layer include: valve disassembly tool, three-grip puller, piston ring special disassembly tool, piston ring clamp, EN-6625 flywheel lock tool, hexagon wrench, spark plug disassembly tool

The tools included in the fourth layer include: pointed nose pliers, long diagonal pliers, short diagonal pliers, carp pliers, vice, oil gun, seat cover, rag, blade, slotted screwdriver, cross screwdriver, Torx screwdriver, rubber hammer.

Tool Portfolio

1. In the exercise mode, you can select a prompt to select a tool for assembly. When assembly errors occur, a prompt message will appear

During the disassembly/installation process of the simulation training, the disassembly of each bolt is subject to the competition level specification mode. The torque setting is fully in accordance with the maintenance manual standards

3. Multiple tool combinations can be supported, including:

Middle ratchet wrenchMedium length extension rod and TX30 Torx head middle sleeve combination tool:

Medium ratchet wrench, medium long extension rod, E12 Torx medium socket combination tool< br />

Medium ratchet wrench, medium short extension rod, E12 Torx medium socket combination tool< br />

Medium ratchet wrench, medium short extension rod, E8 Torx medium socket combination tool

Large ratchet wrench, large short extension rod and 24 # large hexagon socket combination tool< br />

Medium ratchet wrench, medium long extension rod, E12 Torx medium socket combination tool< br />

Medium ratchet wrench, medium short extension rod, E12 Torx medium socket combination tool

Medium ratchet wrench, medium long extension rod, 13 # medium hexagon socket combination tool< br />

Large ratchet wrench, large short extension rod and 24 # large hexagon socket combination tool< br />

Medium ratchet wrench, medium short extension rod, E10 Torx medium socket combination tool< br />

Medium ratchet wrench, medium short extension rod, TX30 box head medium socket combination tool< br />

Medium ratchet wrench, medium short extension rod and HW5 hexagon socket combination tool< br />

Medium ratchet wrench, medium long extension rod, 16 # medium long sleeve combination tool< br />

Medium ratchet wrench, medium short extension rod and TX45 box head medium sleeve combination tool< br />

Medium ratchet wrench, medium long extension rod, E8 Torx medium socket combination tool< br />

Medium ratchet wrench, medium short extension rod, E14 Torx medium socket combination tool< br />

Medium ratchet wrench, medium short extension rod, TX55 box head medium socket combination tool< br />

Middle ratchet wrench, 18 # medium hexagon socket combination tool< br />

25-100 torque wrench, large short extension rod, large rotating joint, E12 Torx socket combination tool< br />

25-100 torque wrench, large short extension rod, large rotating joint, E10 Torx socket combination tool< br />

0-25 torque wrench, medium short extension rod, E12 Torx medium socket combination tool< br />

0-25 torque wrench, medium short extension rod, E8 Torx medium socket combination tool< br />

25-100 torque wrench, large rotating middle joint, 18 # medium hexagon socket combination tool< br />

0-25 torque wrench, medium short extension rod, HW5 hexagon socket combination tool< br />

25-100 torque wrench, large short extension rod, rotating intermediate joint, TX55 Torx socket combination tool< br />

0-25 torque wrench, medium short extension rod, TX45 box head medium sleeve combination tool< br />

25-100 torque wrench, large short extension rod, large rotating joint, E14 Torx socket combination tool< br />

0-25 torque wrench, medium long extension rod, E8 Torx medium socket combination tool< br />

0-25 torque wrench, medium long extension rod, 16 # medium long sleeve combination tool< br />

0-25 torque wrench, medium short extension rod, HW5 hexagon socket combination tool< br />

0-25 torque wrench, medium short extension rod, TX30 Torx medium socket combination tool< br />

25-100 torque wrench, large short extension rod, 24 # large hexagon socket combination tool< br />

0-25 torque wrench, medium long extension rod, 13 # medium hexagon socket combination tool< br />

0-25 torque wrench, medium and long extension rod, TX30 Torx socket combination tool, etc.

Parts table

1. & nbsp; & nbsp;& nbsp; During installation, click“ Parts Table” You can quickly locate the parts table or use the shortcut key“ x” Quickly navigate to the parts table to view the parts removed from disassembly mode, or the parts that need to be installed in installation mode< br />

2. & nbsp; & nbsp;& nbsp; Parts have the functions of installing, viewing, cleaning, and canceling. When installing parts incorrectly, there will be a prompt message< br />

1) & nbsp; & nbsp;& nbsp; Install, go to the corresponding steps, click the parts to be installed, click Install, and place the parts in the corresponding position on the assembly/disassembly console

2) & nbsp; & nbsp;& nbsp; View the 3D mode display of the part, with a 360 degree full view. Components displayed in 3D mode and supporting 360 degree viewing include:

Throttle body, intake manifold, oil conduit, generator, exhaust manifold, exhaust manifold gasket, oil filter oil filter cover, oil filter, thermostat housing, thermostat housing coolant pipe, oil cooler housing, oil filler cap, ignition module cover, ignition module, spark plug, camshaft cover, oil pan, timing belt front and middle cover, crankshaft balancer, timing belt front and lower cover, timing belt, Timing belt tensioner, timing belt idler, camshaft adjuster (inlet), camshaft front bearing cover, timing belt rear cover, camshaft oil seal, water pump pulley, camshaft bearing cover, water pump, water pump seal, crankshaft sprocket, camshaft, valve lifter, engine front cover assembly, front cover gasket, cylinder head< br />

3) & nbsp; & nbsp;& nbsp; Cleaning: Select the cleaning method independently to clean the disassembled parts< br />

3. & nbsp; & nbsp;& nbsp; Place the parts in the order of disassembly or installation< br />

For example, in the installation mode of the cylinder block, the parts are placed in the order from right to left and from bottom to top, followed by the upper bearing shell of the crankshaft, the crankshaft, the crankshaft rear oil seal, the crankshaft position sensor variable resistance magnetic ring, the lower bearing shell of the crankshaft, the crankshaft bearing cap, the crankshaft bearing cap bolts, the cylinder 2 and 3 piston plugs, the lower bearing shells of the cylinder 2 and 3 connecting rods, the cylinder 2 and 3 connecting rod bearing caps, the cylinder 2 and 3 connecting rod bearing cap bolts, the cylinder 1 and 4 pistons, the lower bearing shells of the cylinder 1 and 4 connecting rods, and the cylinder 1 and 4 connecting rod bearing caps, one, 4 cylinder connecting rod bearing cap bolts.

Can

Install the removed parts

Throttle body bolt, throttle body, throttle body gasket, intake manifold, intake manifold gasket, generator retaining bolt, oil conduit, generator, oil conduit retaining bolt, oil conduit seal, exhaust manifold nut, exhaust manifold, exhaust manifold gasket, oil filter cover seal, oil filter cover, thermostat housing coolant pipe bolt, oil filter, thermostat housing, Thermostat housing coolant pipe, thermostat housing coolant pipe bolt, oil cooler housing bolt, oil cooler housing, oil filler cap, oil filler cap gasket, ignition module cover, ignition module plug, ignition module, spark plug, camshaft cover bolt, camshaft cover gasket, oil pan, timing belt front upper cover bolt, timing belt front middle cover, crankshaft balancer bolt, pressure washer, Crankshaft balancer, timing belt front lower cover bolt, timing belt front lower cover, timing belt, timing belt tensioner bolt, timing belt tensioner, oil pan drain bolt, oil pan bolt, timing belt idler pulley bolt, timing belt idler pulley, camshaft adjuster bolt, camshaft adjuster (inlet), camshaft front bearing cover bolt, timing belt rear cover bolt, camshaft front bearing cover, timing belt rear cover bolt, Camshaft oil seal, water pump pulley bolt, camshaft bearing cover bolt, water pump pulley, water pump bolt, camshaft bearing cover, water pump, water pump seal, crankshaft sprocket, camshaft, crankshaft front oil seal, engine front cover bolt, valve lifter, engine front cover assembly, front cover gasket, flywheel bolt, cylinder head bolt, cylinder head.

Cleaning machine

1. & nbsp; & nbsp;& nbsp; After disassembly of parts, select“ Cleaning Machine” After function, independently select the cleaning method to clean the disassembled components

2. & nbsp; & nbsp;& nbsp; The cleaning process can dynamically display the cleaning effect

3. & nbsp; & nbsp;& nbsp; You can set the temperature, time, start or pause, turn on the switch, and extract parts.

service manual

1. Used to store officially issued maintenance manuals, which can be directly opened for reference

Supporting functions of tools

1. Combination function: Combines multiple different tools

2. Decomposition function: When a combination tool is not currently needed, it is decomposed

3. Combination toolbar: displays the current combination tool or exploded tool

4. Tool Return: Return tools that are not currently needed to their original location in the toolbox. Some instruments can be automatically repositioned by clicking on tool repositioning, while others require manual repositioning after disassembly.

Disassembly and assembly stand

The angle of the engine can be adjusted 360 degrees during installation and removal.

Video materials

1. Used to store some video materials related to the maintenance of vehicles in this function module.

allocation function

1. Exit button: Click this button to exit the maintenance scenario

2. Quick positioning button: Clicking this button will automatically adjust the scene to the best viewing angle for the current operation. You can also use the shortcut key“ Z”。

3. Submit Test Paper Button: This function can only be used in actual combat assessment mode.

Operation records

"If an operator wants to check whether there have been non-standard operations or errors in previous operations, they can click“"; Operation Record” View the record of the current module operation

"Operation records include operation steps, operation time, and operation results, and display of non-standard operations“"; The operation sequence is incorrect;.

Main scene

Quickly navigate to the main scene.

Previous step

Exercise mode: During disassembly and assembly exercise, if the disassembly and assembly operation of the previous step does not achieve the best practice effect, you can choose“ Back” Strengthen targeted practice to improve learning efficiency.

Time display

There are time prompts for both the practice mode and the assessment mode.

Prompt information

1. Current operation: The software has corresponding text prompts for each step of operation

2. Prompt for abnormal operation: When the user fails to follow the correct operation process; The software will give voice and text prompts when tools are improperly combined, or when the parameters of the combined tool are set incorrectly or not standardized

3. Display the operation steps in a list form, click any step to jump, and conduct subsequent training operations

4. Each step in the operation step list contains operation decisions

Back & nbsp; platform

Teacher management

1. Addition of teacher accounts (account information: teacher name, teacher account, password, management class)

2. Modify, query, and delete teacher account information

3. Import and export teacher information

Class management

1. Addition of class information (class information: class name, teacher)

2. Modify, query, and delete class information

3. Publish appraisal information.

Student Management

1. Addition of student accounts (account information: name, account, student number, password, teacher)< br />

2. Modify, query, and delete student account information

3. Batch import of student information.

Teaching plan management

1. Add a teacher's lesson plan (including the lesson plan name and chapter)

2. Edit, delete, download, and query the teaching plan

Courseware Management

1. Add a teacher's courseware (including the courseware name and chapter)

2. Editing, deleting, downloading, and querying courseware

job management

1. New class assignments (including assignment name, chapter, class, and deadline for students to submit assignments)

2. Perform operations such as editing, deleting, downloading, and querying jobs

Appraisal Record Management

1. Teachers can view and delete detailed operational step information, self-uation, teacher comments, and other information about students' assessment in actual combat assessment.

Training Record Management

1. The teacher can view and delete detailed operation step information, self-uation, teacher comments, etc. of students practicing in the training base.

Data backup restore

1. Remote backup and recovery of data

2. Local backup and recovery of data

3. Depending on the way the software is installed, you can choose to remotely backup and restore data; Restore data from a local backup.

Product Introduction

Product Introduction